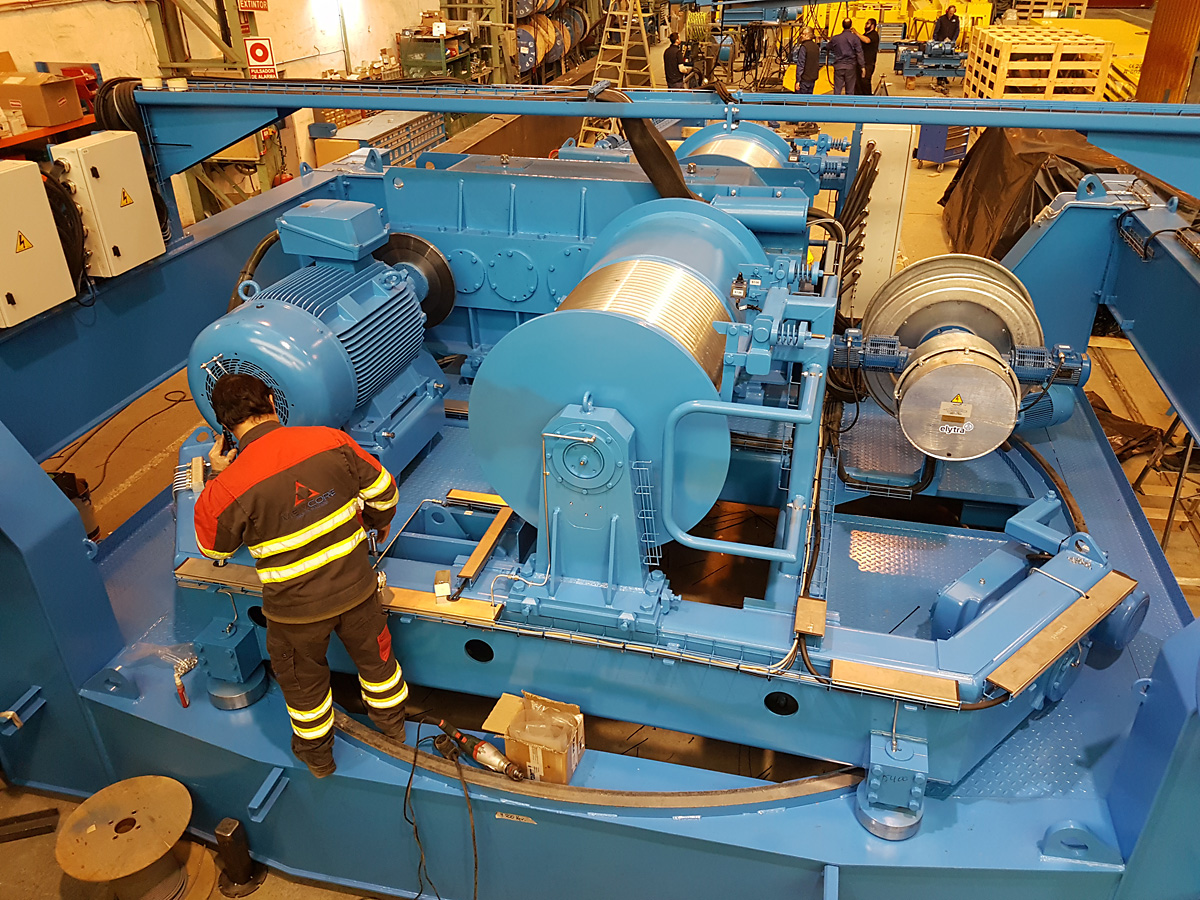

GH has recently installed a bridge crane with an open, rotating trolley (2 x 20t / 16t) and a series of features that makes this installation special:

- Process cranes – high-performance cranes designed to work in extreme conditions, at high temperatures, and all day long.

This particular case is a billet crane with a rotating trolley and magnets to handle hot billets.

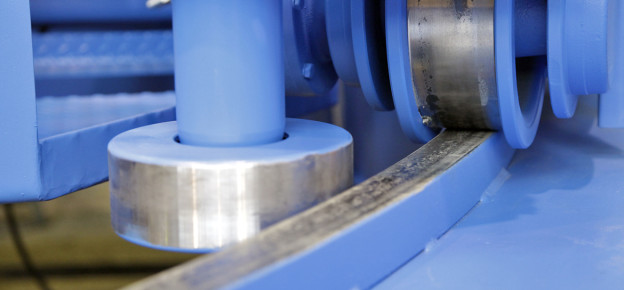

- Work group classification M7, robust design, and the most reliable materials provide completely reliable lifting equipment.

Continuous jobs and extreme conditions: this specific one at an ambient temperature of 80 ºC handling billet at 600 ºC.

- Speeds adapted to the production needs in order to complete the cycles required by the process itself.

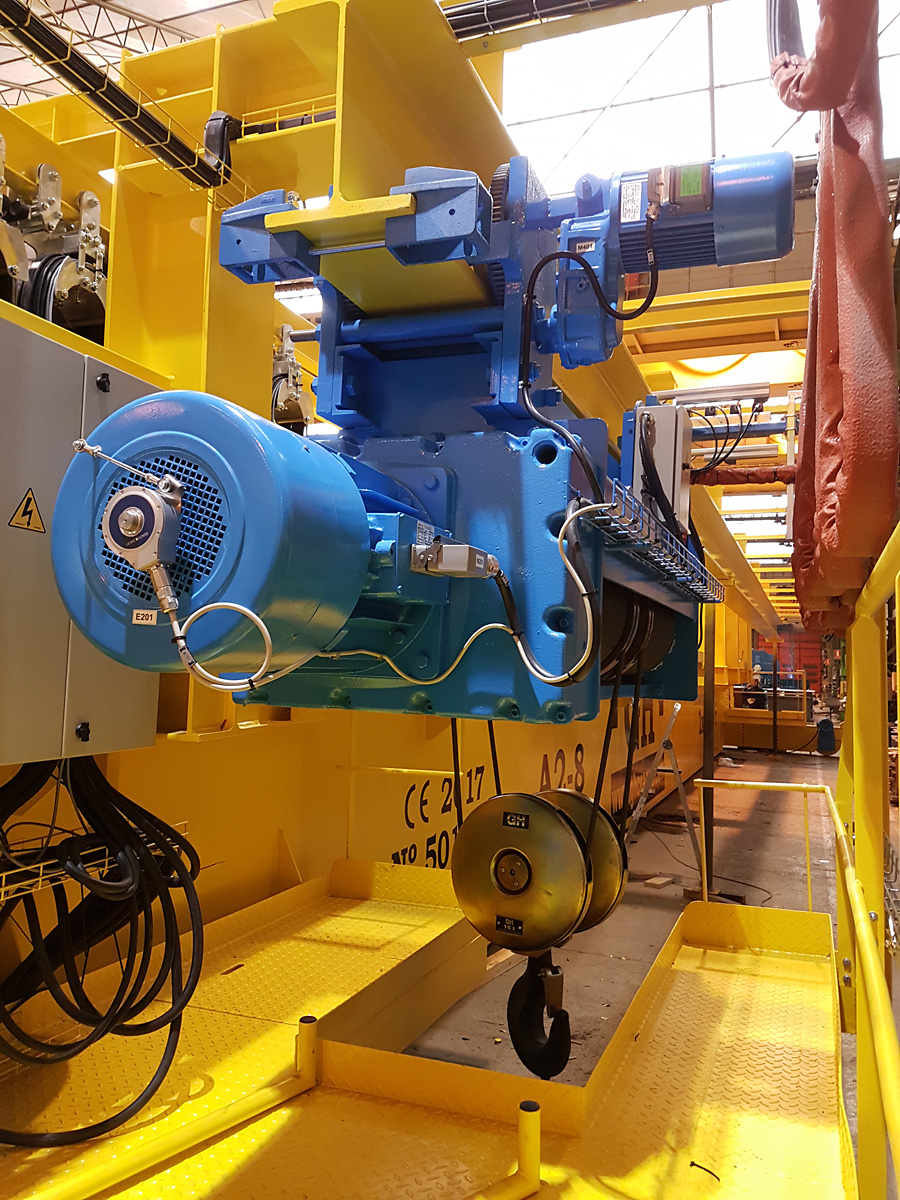

- Auxiliary hoists for the maintenance of the rest of the installation. In this case, a lifting hook with a 16t lifting capacity to undertake plant maintenance tasks.

This bridge crane is installed in a building that spans 26 metres, with 22-metre lifting heights (with a pit). The equipment has a 16t auxiliary hoist to undertake maintenance at the facilities (the hoist is installed on a cantilever-type structure to ensure the best approaches as it crosses the building).

Other outstanding features of this crane, classified in group M7, include the weighing system + traction cells, area and manoeuvring boundaries, automations for management, etc.

The electrical equipment is installed in a separate cabin equipped with redundant industrial cooling in order to guarantee the capability to work at high temperatures.