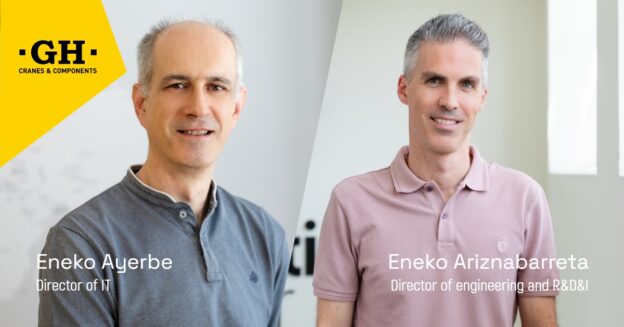

En GH Cranes & Components estamos desarrollando una serie de proyectos innovadores para integrar la inteligencia artificial en nuestros procesos y productos, con el objetivo de mejorar la eficiencia, la seguridad y la competitividad. A continuación, describimos los seis principales proyectos en los que estamos trabajando actualmente Sigue leyendo