We cater to the needs of our customer, adapting our cranes so that they meet the established requirements.

Our production capacity allows us to manufacture a weekly average of 70 standard overhead cranes. However, not all crane project requirements match our standard products.

In these cases, the Special Solutions Unit studies and configures the characteristics of the crane to adapt it to the requirements and needs of the customer.

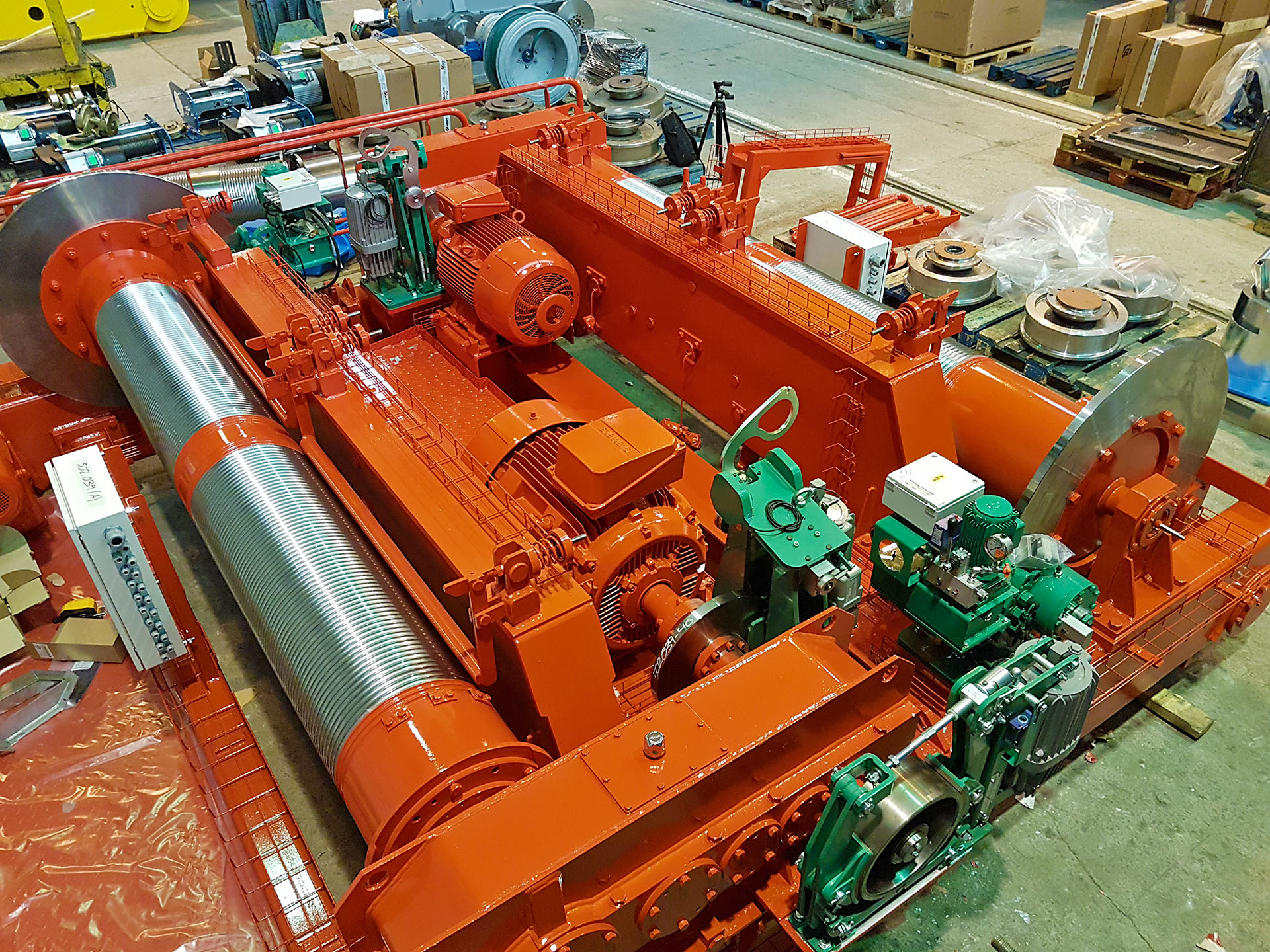

An example of this customisation is this trolley with redundancy in the lifting safety system developed for the company Zhejiang Luhu Automobile, for their facilities in Linhai City, in the province of Zhejiang (China).

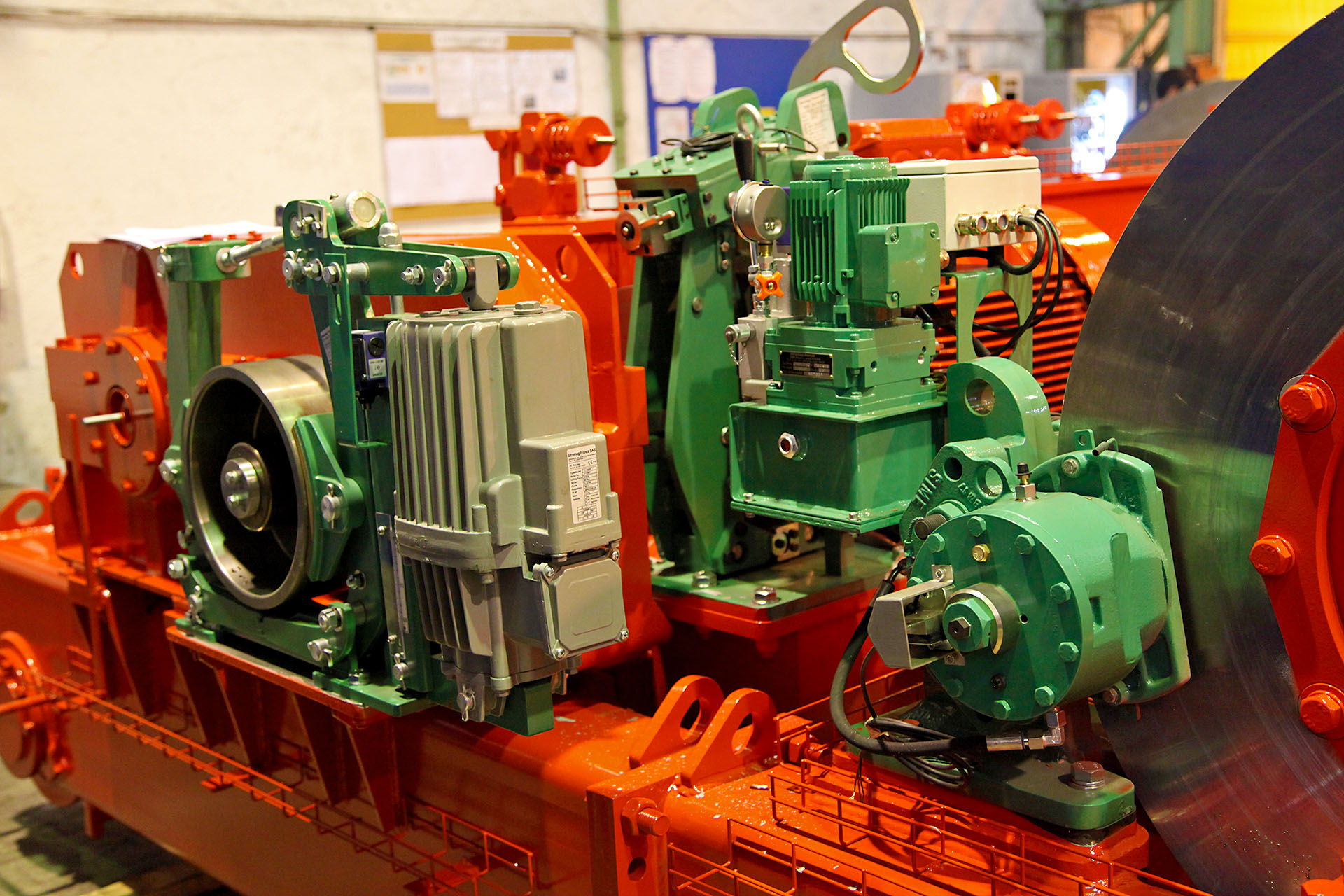

The trolley in question is mounted on a double girder overhead crane with a span of 28.5 m and a lifting height of 13.7 m. This open winch, which is M6 duty has a Siemens motor and a GHF-4T gearbox and has 3 brakes installed in the main lifting system:

- Service brake on the motor shaft.

- Auxiliary brake on the motor shaft.

- Emergency brake on the drum.

It also has manual brake release for cross and long travel motions.

The crane also includes anti-sway and overspeed in hosting motion.