FAGOR ARRASATE celebrates ten years in China.

A few days ago, in Kunshan, GH joined the celebration of the tenth anniversary of the establishment of FAGOR ARRASATE in the Land of the Red Dragon.

This Mondragón Group company is one of the leading companies in the field of capital goods on the international scene.

FAGOR ARRASATE is a worldwide specialist in the design, manufacture and supply of machine tools for metal forming, from presses and complete stamping systems to production lines for manufacturing, processing and cutting sheet metal and special complete lines for manufacturing complex sheet metal parts.

With six plants in different parts the world, the Mondragón company asserts its global presence in all the major international markets with products in seventy countries.

Founded in 1957, it is now a benchmark, being a world leader in terms of the number of installed production lines and the prestige of its products, technology, quality and research and development. Practically all the major manufacturers of motor vehicles, stamped parts, coils and other steel and aluminium products, electrical appliances, metal furniture, forged parts and electric laminates in the world have FAGOR equipment.

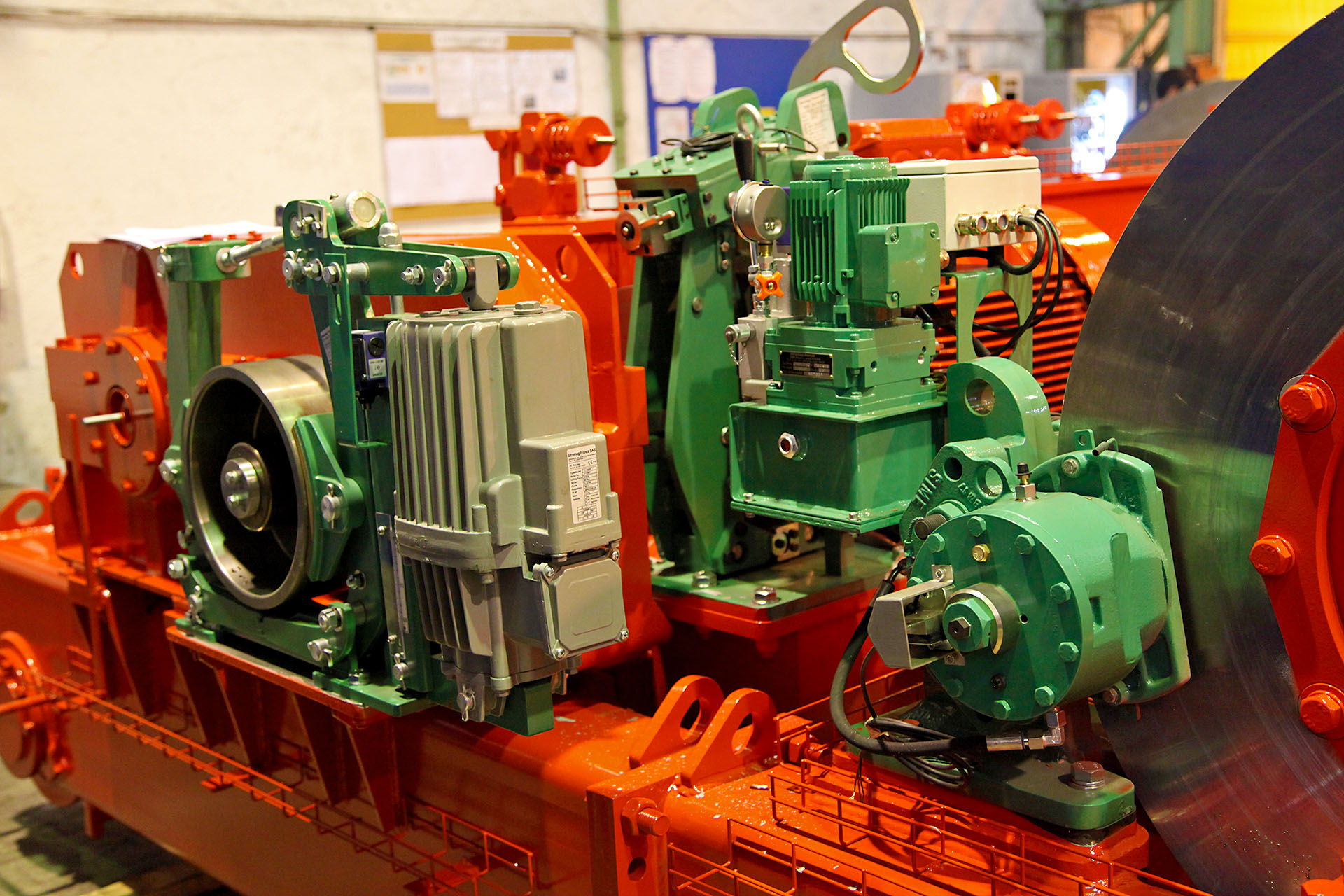

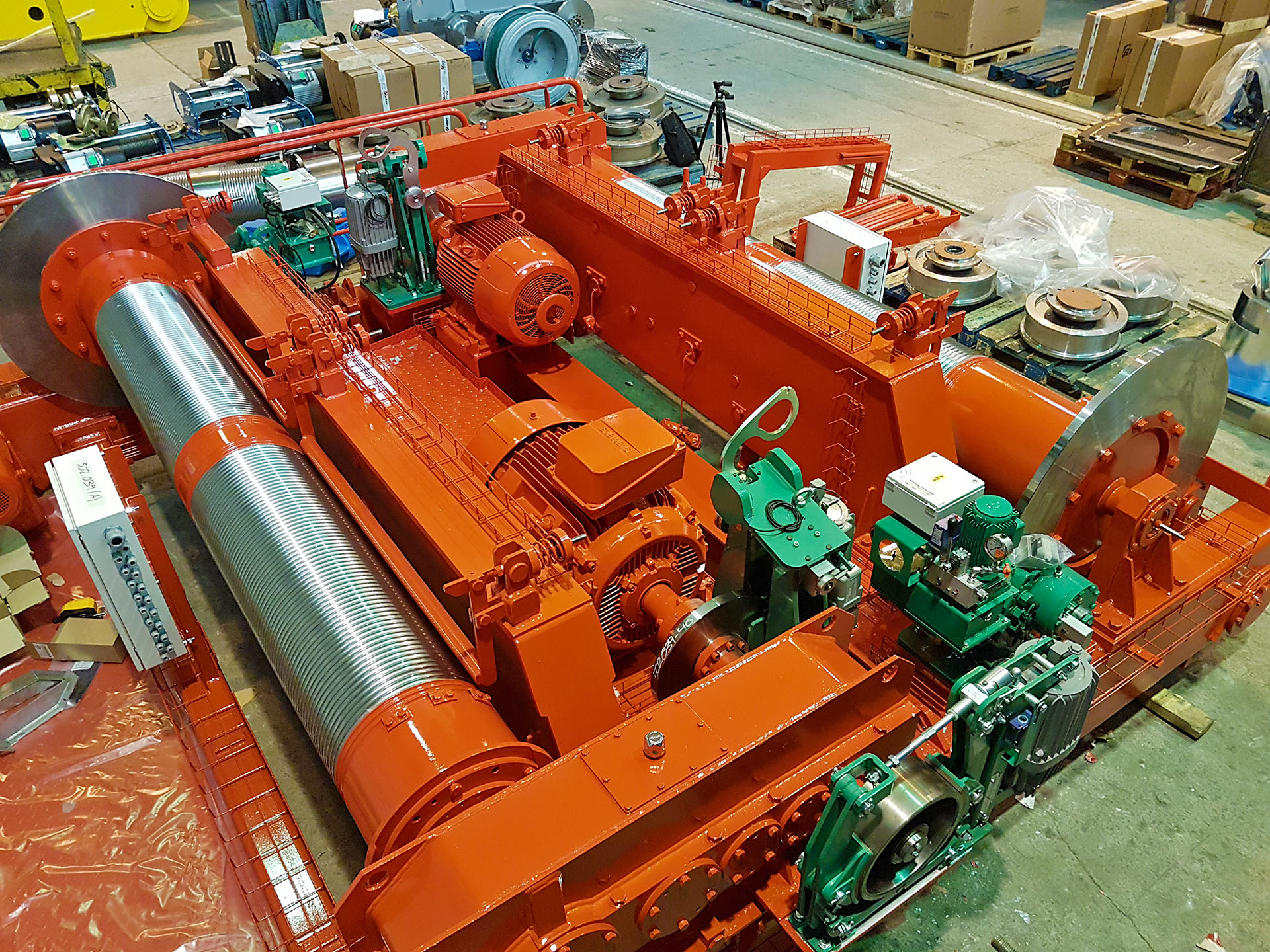

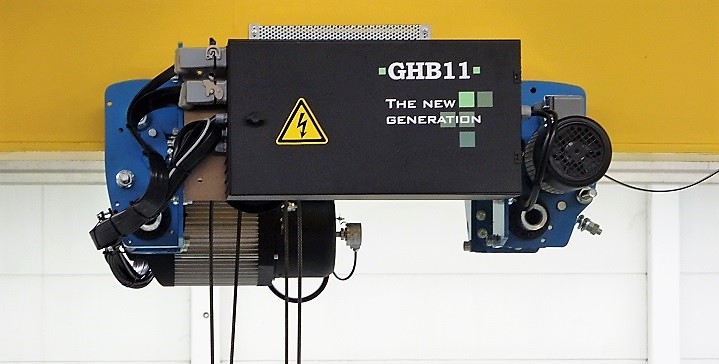

In the presentation that took place in China, GH had a notable presence in the form of the cranes supplied by our company. FAGOR ARRASATE is one of the major players in the sector in the Chinese market.

It is important to highlight the message rooted in our international expansion plan: GH travels the world and helps the world’s leading companies to grow.

This celebration is confirmation of that fact.