This initiative is aimed at Start-ups and companies in the process of creation, with a business project related to the fields of activity GH CRANES.

GH CRANES is interested in business projects in one of the following areas:

Safety systems

Safety first. Safety in the handling of our cranes is the number one priority for GH CRANES. The continuous evolution of the state of the art in the field of sensors and wireless communication systems provides an opportunity to explore new ways to equip our cranes with advanced security systems.

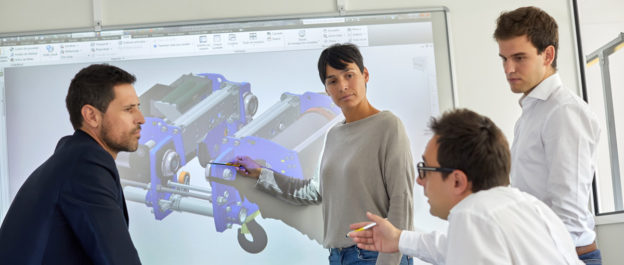

Automation

The automation of cranes is no longer an option, but rather a necessity in many productive processes where industrial cranes operate. True to our commitment to provide more standard features at a competitive price, we set ourselves the challenge of evolving our portfolio of existing automation solutions to the next level.

Digitisation and data analysis

At GH we have carried out a strategic analysis of the impact that the fourth industrial revolution has on our business. Our commitment to taking advantage of the advances in the Internet of things, connectivity and digitisation of processes have allowed us to develop new services geared towards after sales that we want to develop with your help.

More information about the GH START-UP CONTEST project in this link.