We have improved our low headroom single girder hoists.

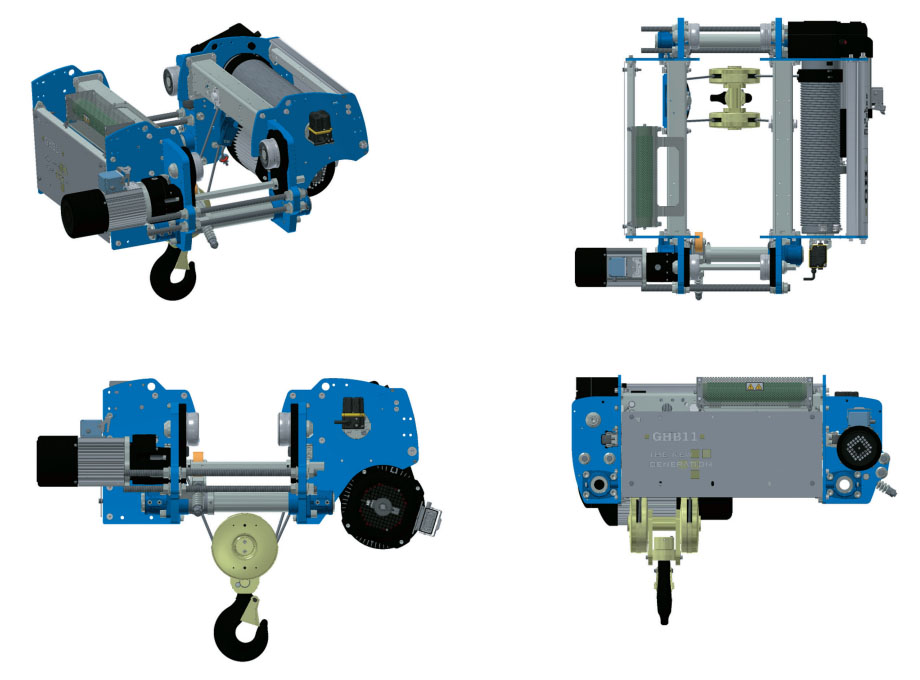

Following our line of continuous improvement and evolution of our products, we have improved the performance of the GHB11 reducing height hoist, making it safer, making easier the maintenance with a compact design.

The new GHB11 reduced height hoist just come and brings the following improvements:

REPLACING RING-BLOCK BY CASTING PIECE:

- New supports that facilitate the assembly and give more rigidity to the frame, reduction of 35% in times of assembly in beam.

- The range of the new generation hoists is homogenized.

- Elimination of the reinforcements of the car sheet.

- Easy maintenance.

SUPPORT INCORPORATION FOR FIXED POINT IN EXECUTIONS 2/1:

- It allows a better balance of the loads with respect to the axis of the beam.

- Mitigates the problems of twisting or twisting in the beams manufactured with profiles type H.

RELOCATION OF THE BRAKING RESISTOR:

- More integrated resistance inside the hoist.

ROOF TILES:

- Height is gained by repositioning the braking resistor.

- You get supports similar to the other models.

ROLL OVER:

- The support has been redesigned to resemble those of GHA12 and GHD13.

REDESIGN OF THE UPPER AREA OF THE SIDE PLATES TO GAIN HEIGHT:

- In this way, the hoist is more compact.

It can be requested through GH1WEEK from October 4th .

One more step in our way to add value to our products at reasonable prices and answer to the true needs of our customers making a difference in the market.