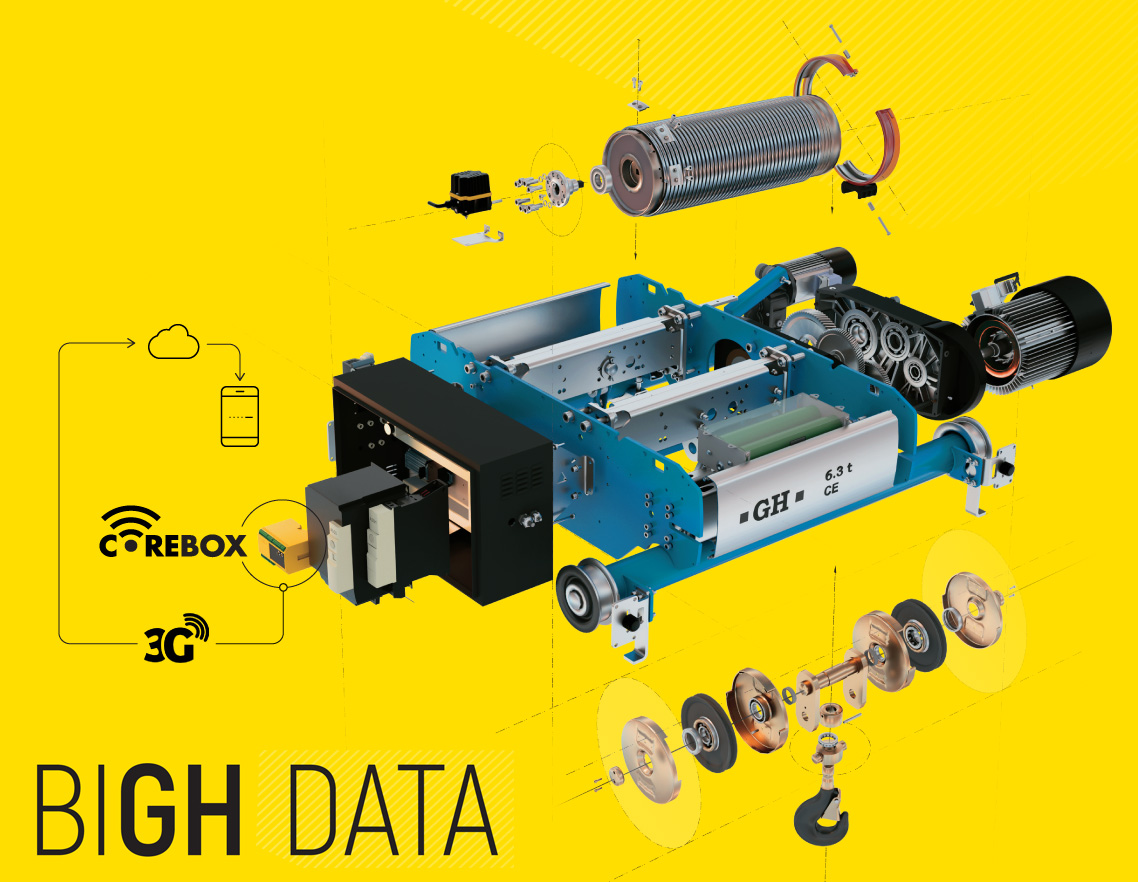

Un claro ejemplo del valor añadido que ofrecemos en el servicio post-venta.

Esta plataforma digital de análisis y almacenamiento de datos, desarrollada entre GH Cranes e IKERLAN, informa de manera remota sobre el estado de las grúas instaladas en las plantas de nuestros clientes, en el ámbito mundial.

Este proyecto se enmarca dentro del desarrollo del Corebox, el cual concentra gran parte del esfuerzo en innovación que estamos llevando a cabo en los últimos años.

Aplicando las soluciones de la plataforma Ikerlan Konnekt, conseguimos conectar, recopilar y enviar la información de las grúas a la nube. Un sistema escalable y seguro que nos permite procesar grandes volúmenes de datos.

Los datos recogidos en una plataforma Cloud, se procesan para obtener información histórica y técnica, lo que nos permite optimizar el rendimiento de las grúas y establecer un mantenimiento predictivo. De esta manera se optimiza el funcionamiento de las grúas y se reducen los coste de explotación.

Esta información se gestiona a través de nuestra aplicación «Portal cliente».