Estas grúas pórtico han sido suministradas a Stecon, a lo largo del último año, a través de nuestra filial en Tailandia LGHCRANES.

Las dovelas son parte fundamental en la construcción de túneles y en proyectos de obra civil, puesto que recubren a modo de anillo las paredes del túnel, formando una superficie solida y resistente.

Las dovelas que conforman el anillo tienen geometrías distintas según su posición en el anillo. Estas dovelas se montan en el túnel al abrigo de la coraza del escudo mediante el encaje de unas con otras, atornillándose en las juntas, circunferenciales y radiales.

Para el proyecto de los túneles de Bangkok, que está desarrollando la ingeniería Stecon, especialista en obra civil e infraestructuras, se requieren numerosas piezas de dovelas prefabricadas de hormigón armado, las cuales se almacenan en las campas próximas a la boca de acceso al foso.

Las campas cuentan con varios pórticos GH Cranes para el almacenado y distribución de las dovelas. Son 7 grúas pórticos que tienen montados dos polipastos birraíl de 50tn de capacidad y una altura de elevación de 18m, cada una. La luz de los pórticos es de 37,23m. Los polipastos montados en cada una de estas unidades pueden trabajar independientes o sincronizados.

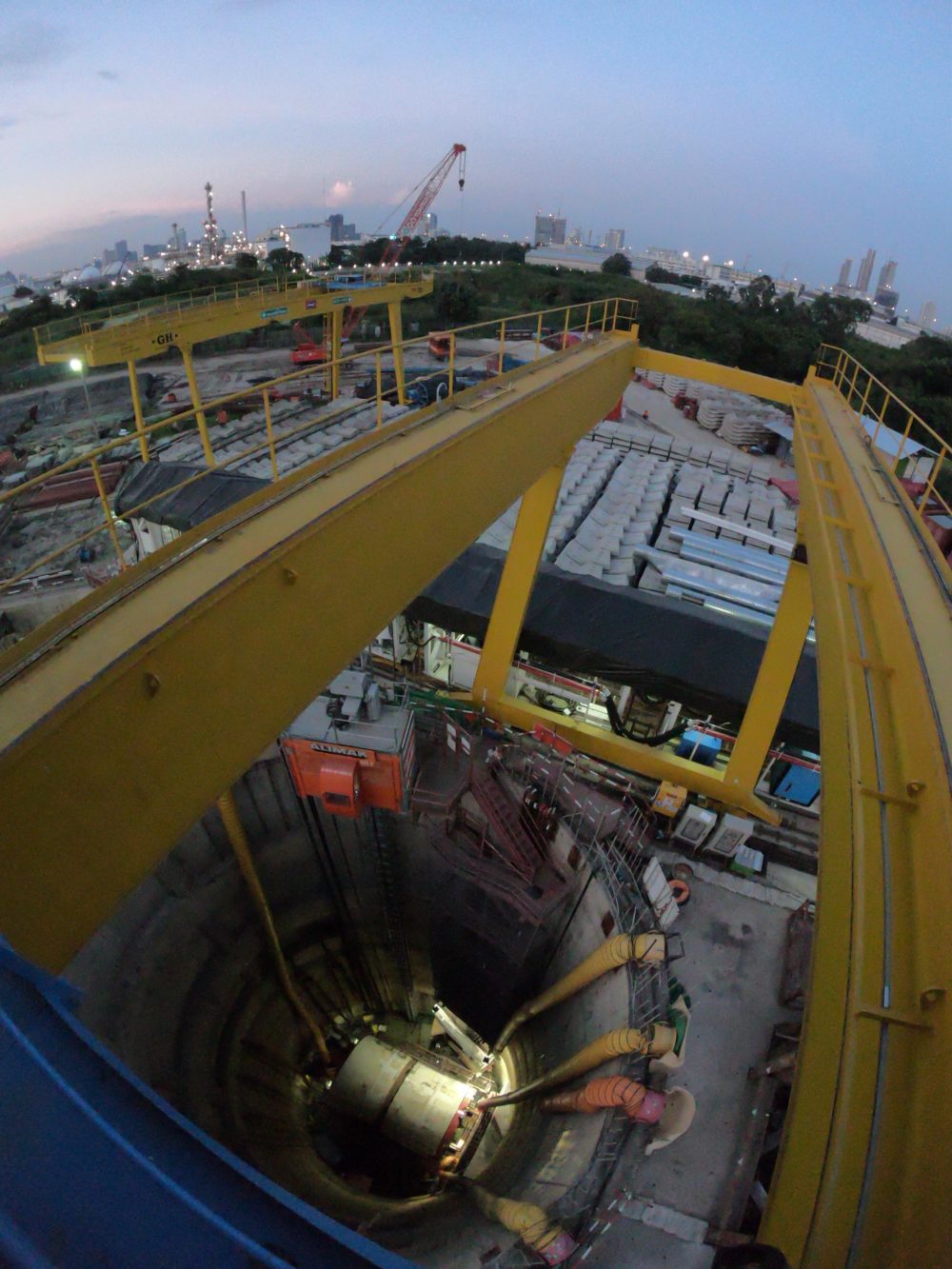

Además de estas 7 unidades, la instalación cuenta con otras 4 grúas pórticos encargadas de suministrar las dovelas a la tuneladora, a través del foso. Durante el proceso de perforación la tuneladora va revistiendo las paredes del túnel con estas dovelas, por lo que se requiere un suministro fluido de piezas para poder mantener el avance de la tuneladora.

Estos pórticos tienen una luz de 18m, con 4m de voladizo a cada lado y una altura de elevación de 9,5m + 32m de foso, teniendo dos de ellos capacidad de 22t y otros dos de 10t. La velocidad de elevación de los pórticos de 22t es de 30m/min y los mecanismos están desarrollados en grupo de trabajo M8. Estos equipos también destacan por llevar freno de seguridad de tambor.

Un quinto pórtico de capacidad de 2x80t y se utiliza para el manejo de los bloques grandes de prefabricados.

Ver vídeo del pórtico de 2x80t.

Para este proyecto GH Cranes se ha encargado de suministrar los kits de pórtico a LGHCRANES, quien se ha encargado de completar la fabricación de los productos y realizar el montaje en las instalaciones del cliente.

A lo largo del año se han instalado varios equipos en Tailandia para Stecon:

- Campa de Nonthaburi: Instalación de siete pórticos de 2x50t para producción de segmentos de hormigón, bloques para viaducto.

- Bangkok, distrito de Bangna: Instalación de pórtico de 22t para foso (trabajos de extracción lodo, tuneladora, y dovelas), y pórtico de 10t, con luz de 18m y altura de elevación 9,5m en M5, para campa de stock.

- Bangkok, distrito de Prawet: Instalación de pórtico de 22t para alimentación de dovelas en foso.

- Bangkok: Instalación de puente birraíl de 25t con luz 8m y altura de elevación 61m.

- Chonburi: Pórtico ya suministrado y pendiente de instalar otro pórtico de 10t.

Además de estas instalaciones, en los últimos años se han fabricado otras unidades para los proyectos de Stecon:

- En 2014 provincia de Nonthaburi: Instalación del primer pórtico, 63+63t y luz de 36m para producción de segmentos.

- En 2016 misma campa de Nonthaburi: Cuatro grúas puente de 5+5t para trabajos auxiliares.