In the latest GH low headroom hoists we’ve removed the counterweight, by adding a sprung roller made of cutting-edge materials which supports the hoist’s weight when it is unloaded.

With this, what benefits do our customers have?

They can have smaller runway beams and use less building materials.

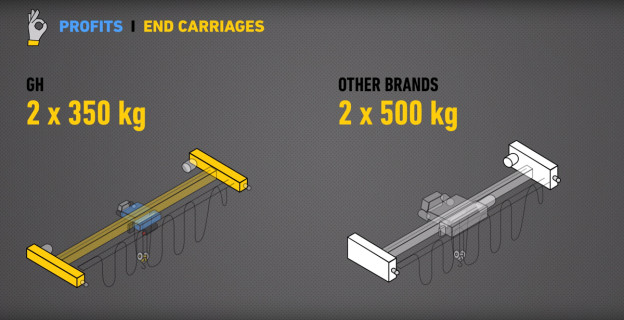

This optimisation of the hoist’s and girder’s weight makes an important weight difference when compared to other brands.

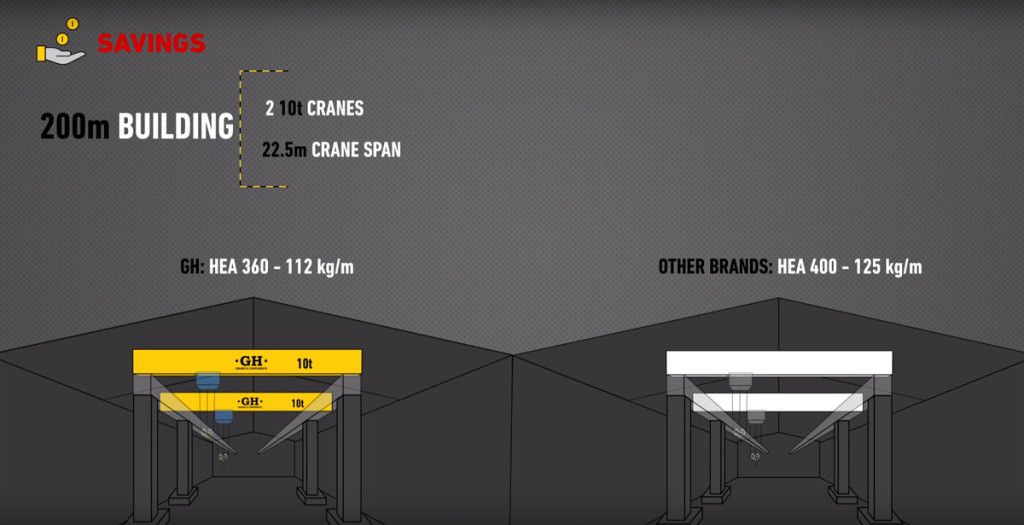

For example, if we have a building of 200 metres, 22.5 metres of crane span, two cranes with a 10t capacity per building, two runways per building and a cost of 1.5 euros for each rail kilo.

Doing the math, we’ll see that that the savings amount to 7.800 euros in the cost of the runway beams.

And that’s not all, because the vertical load per wheel decreases 8%, which brings about savings of 7% in building materials.

To sum up, GH has developed an innovative hoist: lighter than our competitors’, but equally robust. As a result, the runway beams are smaller, less building materials are needed and money is saved.

For more information: https://www.ghcranes.com/en/information/videos/7-key-questions-for-a-crane-manufacturer-of-xxi-century/