These gantry cranes were supplied to Stecon over the course of the last year through LGHCRANES, our subsidiary in Thailand.

Precast invert segments are a fundamental part of tunnels construction and civil work projects, given that they cover tunnel walls like a ring, thus creating a solid, durable surface.

The precast invert segments that make up the ring have different geometries, depending on their position in the ring. These precast invert segments are mounted on the tunnel to protect the shell of the shield by placing them together and screwing them in at the circumferential and radial joints.

For the Bangkok tunnels project, being currently developed by the Stecon engineering firm, a specialist in civil works and infrastructures, numerous precast reinforced concrete invert segments are required, which are stored in the yards near the pit’s access point.

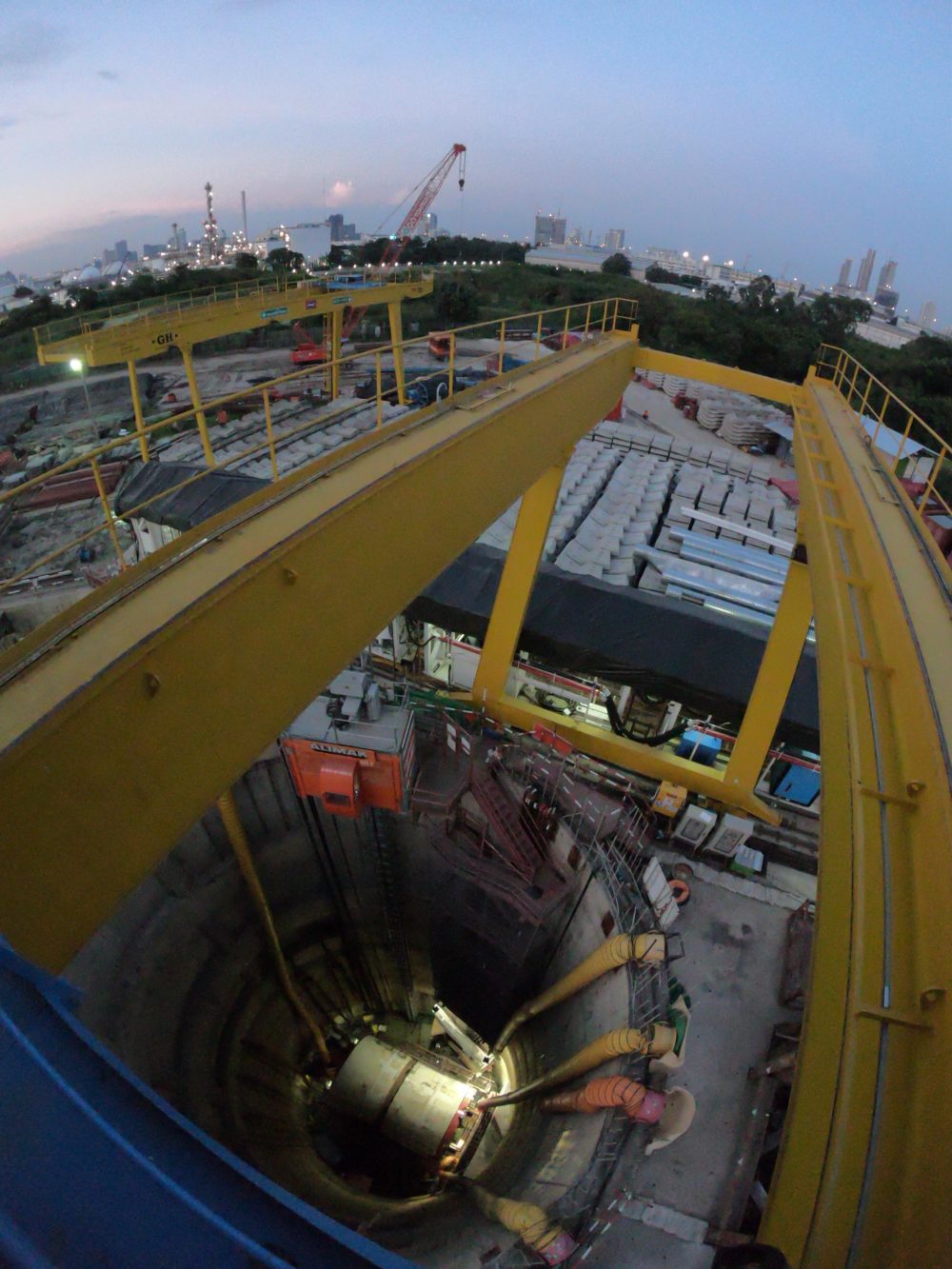

The storage yards have various gantry cranes from GH Cranes to store and distribute the precast invert segments. Seven gantry cranes are in place with two 50t capacity travelling wire rope hoists and 18m lift height each. The gantry cranes have a 37.23m span. Each of these units’ wire rope hoists can work independently or in unison.

In addition to these 7 units, the location has 4 other gantry cranes, which are responsible for supplying the tunnelling machine with precast invert segments through the pit. During the drilling process, the tunnelling machine reinforces the tunnel’s walls with these precast invert segments, which means that a steady supply of segments is required in order for the tunnelling machine to continue advancing.

These gantry cranes have a 18m span, with 4m overhang on each side and a lifting height of 9.5m + 32m in the pit. Two of these cranes have a 22t capacity, and another two have a capacity of 10t. The 22t gantry cranes’ lifting speed is 30m/min, and the mechanisms are developed in work group M8. These units also stand out because of their drum safety brake.

A fifth, 2x80t capacity gantry crane is used to handle large prefab blocks.

For this project, GH Cranes has tasked LGHCRANES with supplying the gantry crane kits, and the company will be responsible for completing products manufacture and assembly at the client’s facilities.

Over the course of the year, various units were installed in Thailand for Stecon:

- Nonthaburi storage area: Installation of seven, 2x50t gantry cranes for the production of concrete segments and blocks for a viaduct.

- Bangkok, Bangna district: Installation of a 22t gantry crane for a pit (mud extraction works, tunnelling machine, and precast invert segments), and a 10t gantry crane with a 18m span and M5 lifting height of 9.5m for a stock storage area.

- Bangkok, Prawet district: Installation of a 22t gantry crane to supply precast invert segments to the pit.

- Bangkok: Installation of a 25t overhead crane with 8m span and a lifting height of 61m.

- Chonburi: One gantry crane that had already been supplied but not installed, and another 10t gantry crane.

In addition to these facilities, other units have been manufactured in recent years for Stecon projects:

- In 2014, Nonthaburi province: Installation of the first, 63+63t gantry crane with a 36m span for segments production.

- In 2016, the same Nonthaburi storage area: Four, 5+5t bridge cranes for auxiliary work.